In the rapidly advancing industrial landscape of 2026, essential industrial control systems training is vital for equipping modern workforces with the skills to manage complex automation environments. This training encompasses Rockwell Automation training courses, industrial automation training software, and unlimited user site license training options that align with the Rockwell Automation curriculum. For training managers and tech college instructors, integrating Allen-Bradley training courseware and automation training site licenses ensures unlimited access for teams, fostering proficiency in programmable logic controllers (PLCs), supervisory control and data acquisition (SCADA), and distributed control systems (DCS). Automation training site license As industries face skills gaps and technological shifts, such training not only enhances operational efficiency but also promotes safety and innovation, making it indispensable for contemporary manufacturing, energy, and process sectors.

The Role of Industrial Control Systems in Modern Industries

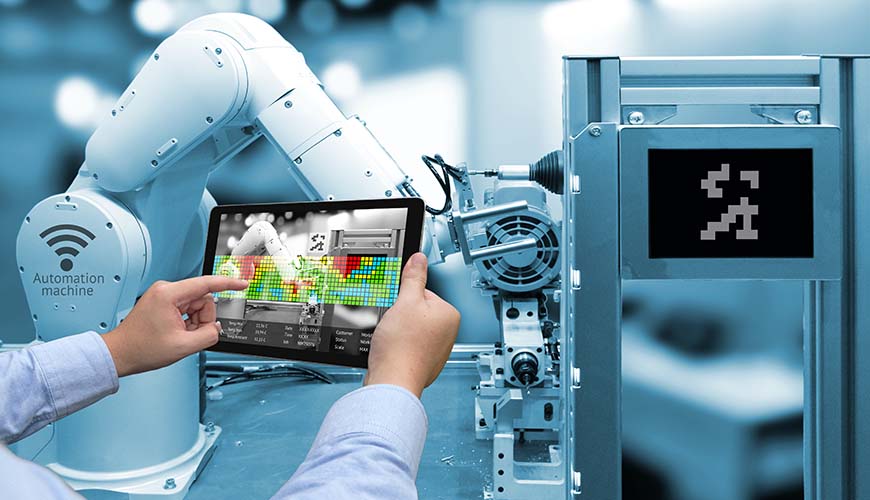

Industrial control systems (ICS) form the backbone of automated operations, controlling processes in sectors like manufacturing, utilities, and transportation. In 2026, with the integration of IoT and AI, ICS training must cover cybersecurity, network configuration, and real-time data management to mitigate risks and optimize performance. Rockwell Automation's workforce development programs emphasize this, offering courses that address these evolving needs through hands-on experiences. Essential training includes fundamentals of AC/DC motors, Ethernet/IP networks, and motion control, as outlined in their training catalog, which provides skill-building in concepts and terminology crucial for modern workforces. By adopting unlimited user site license training, organizations can scale these programs, allowing multiple employees to access industrial automation training software without additional costs, ensuring broad competency in ICS operations.

Key Components of Effective ICS Training Programs

Effective industrial control systems training programs incorporate a blend of theoretical knowledge and practical application, often through instructor-led sessions, e-learning, and virtual simulations. Rockwell Automation's 2026 schedule, effective from January 5, includes courses like Industrial Electrical Controls Fundamentals and Essentials of Industrial Ethernet Networks for OT Professionals, spanning multiple locations and formats. These components focus on core skills such as PLC programming, HMI configuration, and troubleshooting, aligned with the Allen-Bradley training courseware. Providers like BIN95 offer comprehensive Rockwell Automation control concept training series under site licenses, covering topics from basic controls to advanced systems, ideal for unlimited users in educational or corporate settings. Additionally, hands-on labs in courses like those from Intellect Controls Group prepare troubleshooters for real-world scenarios, including electronic control of hydraulic systems and plant-specific equipment. This modular approach ensures that training is adaptable, addressing specific workforce needs while promoting certification in areas like Logix Designer and PowerFlex drives.

Rockwell Automation's Contributions to ICS Training

Rockwell Automation plays a pivotal role in delivering essential ICS training through its extensive curriculum and innovative delivery methods. Their Learning+ platform provides self-paced e-learning modules with knowledge assessments, requiring 80% scores for certificates, covering industrial automation and control technologies. In 2026, remote courses like Studio 5000 Logix Designer Level 1: ControlLogix Fundamentals are available, priced accessibly and delivered in English, catering to global workforces. The instructor-led schedule includes specialized training in motion control using Kinetix 5700 servo drives and EtherNet/IP troubleshooting, scheduled across various U.S. regions to enhance accessibility. By offering automation training site licenses, Rockwell enables unlimited user access, reducing the impact of skills gaps and supporting continuous professional development in ICS.

Benefits for Modern Workforces and Organizations

Investing in essential industrial control systems training yields significant benefits, including improved productivity, reduced downtime, and enhanced safety for modern workforces. Through Rockwell Automation training courses, employees gain proficiency in industrial automation training software, leading to better process optimization and error reduction. Unlimited user site license training models, as provided by BIN95, allow cost-effective scaling, with perpetual access for entire facilities, fostering a culture of ongoing learning. Training managers report higher employee retention and morale, as certifications from programs like the Accelerated Logix5000 Maintainer Certificate validate skills and open career paths. In hands-on sessions, such as those focusing on PLC/HMI trainers, participants engage in labs for sequence logic programming, directly translating to operational efficiency in industrial settings. Overall, these benefits align with 2026 industry demands, where agile, skilled teams are crucial for competitive advantage.

Implementation Strategies for ICS Training

Implementing industrial control systems training effectively requires strategic planning, starting with needs assessments to identify skills gaps. Industrial automation training software Organizations can leverage Rockwell Automation's hybrid models, combining e-learning with instructor-led sessions, as seen in their 2026 calendar with classes in locations like Santa Clara and Phoenix. Adopting unlimited user site license training ensures broad access, with providers like Rexel offering courses such as Essentials of Industrial Ethernet Networks, scheduled from June 2026. Tech college instructors can integrate Allen-Bradley training courseware into curricula, using virtual platforms for remote delivery. Regular updates and partnerships with distributors facilitate customization, while tracking tools in Learning+ monitor progress and ROI. This proactive approach minimizes disruptions and maximizes the impact of training on workforce capabilities.

Future Trends in ICS Training

As we look toward the future in 2026 and beyond, industrial control systems training will increasingly incorporate emerging technologies like AI-driven predictive maintenance and advanced cybersecurity protocols. Rockwell Automation's evolving curriculum, including courses on digital twins and sustainable automation, prepares workforces for these trends. The shift toward paperless, device-agnostic learning enhances accessibility, while site licenses support lifelong learning in dynamic environments. With global events and remote options expanding, training will become more inclusive, addressing diverse workforce needs.

In conclusion, essential industrial control systems training is a cornerstone for modern workforces, empowering them through Rockwell Automation training courses, unlimited user site license training, and comprehensive curricula. By embracing these resources, organizations can navigate the complexities of automation, driving efficiency and innovation. With over 850 words, this exploration highlights the critical importance of such training in sustaining industrial progress.